Opening the Possible: Bolts and Machining Solutions for Seamless Workflow

In the intricate landscape of commercial operations, the function of bolts and machining remedies often goes unnoticed, yet their significance in making sure reliable and smooth procedures can not be overemphasized. The mindful selection of fasteners and the utilization of accurate machining techniques are critical in attaining a seamless combination that can raise functional efficiency to new elevations. By delving right into the realm of bolts and machining services, a globe of untapped possibility and enhanced performance awaits those that are eager to check out the opportunities that exist within.

Significance of Choosing the Right Bolts

Selecting the proper fasteners is vital for ensuring the architectural stability and longevity of any type of assembly. The selection of bolts can considerably influence the efficiency and reliability of the last item. By utilizing the ideal fasteners, designers and suppliers can boost the overall top quality of the setting up and minimize the risks of failure or early wear.

One essential consideration when picking bolts is to match the material of the bolt with the materials being signed up with. Compatibility in between the bolt and the substratum is important to protect against deterioration and make sure a protected link.

Enhancing Accuracy With Machining Solutions

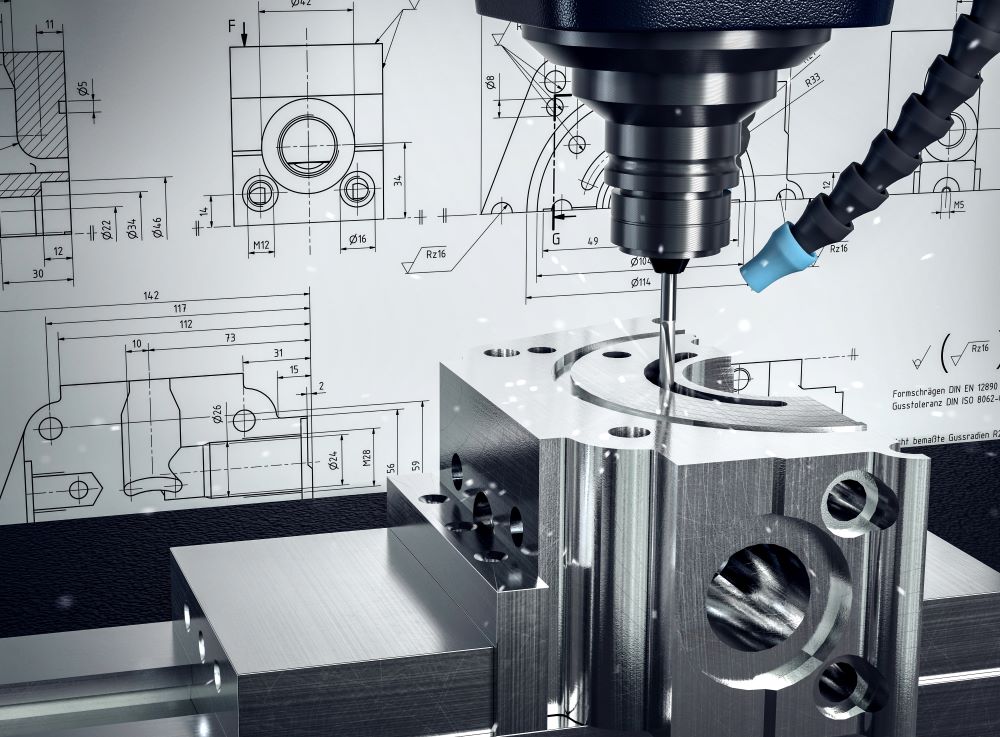

Utilizing advanced machining services can considerably boost the accuracy and performance of manufacturing processes. Precision in machining is crucial for guaranteeing that components meshed perfectly, minimizing the demand for rework and improving the total top quality of the end product. By leveraging sophisticated machining technologies such as Computer Numerical Control (CNC) devices, suppliers can achieve limited resistances and complex layouts with convenience.

In addition, progressed machining services provide capabilities such as multi-axis machining, high-speed cutting, and integrated automation, which improve manufacturing processes and improve overall precision. These modern technologies enable producers to generate complicated get rid of very little error, causing higher productivity and cost financial savings over time.

In addition to precision, machining solutions also play an essential role in improving uniformity across production sets. By configuring machining procedures to exact specifications, manufacturers can reproduce the exact same high-grade outcomes consistently, making certain harmony in the last products. In general, buying innovative machining remedies is vital for producers looking to raise their precision capabilities and achieve smooth operations.

Making The Most Of Performance in Workflow

Enhancing functional performance is paramount for making best use of efficiency and lessening costs in producing processes. Simplifying operations with reliable use sources, maximizing workflows, and lessening downtime are essential for accomplishing this goal. One vital facet of making best use of effectiveness in operations is carrying out lean production principles. By getting next rid of waste, systematizing procedures, and continuously improving operations, business can improve their total efficiency.

Making use of innovative innovations such as automation, robotics, and data analytics can additionally play a significant role in optimizing operations (Fasteners and Machining). These modern technologies can help in reducing manual work, enhance accuracy, and offer real-time understandings for much better decision-making. Furthermore, purchasing staff member training and growth can improve ability degrees and ensure that employees are outfitted to take care of jobs successfully

Collaborating closely with vendors to enhance supply chains and applying just-in-time stock systems can even more enhance efficiency by decreasing lead times and decreasing excess stock. Overall, by concentrating on optimizing effectiveness in operations, business can boost their competition, improve consumer satisfaction, and attain sustainable growth in the lengthy term.

Seamless Combination of Bolts and Machinery

To achieve seamless combination, suppliers require to carefully choose bolts that meet the particular requirements of the equipment being assembled. Aspects such as material compatibility, rust, stamina, and size resistance are essential considerations in picking the ideal bolts. Additionally, using advanced machining techniques and technologies can even more enhance the integration procedure by making sure precise suitable and placement of fasteners within the equipment components.

Influence on Efficiency and Top Quality

The smooth combination of fasteners and machinery substantially influences both performance and quality in making procedures. Fasteners and look at more info Machining. By carefully choosing the ideal bolts and machining solutions, producers can improve their production procedures, leading to boosted effectiveness and result.

Final Thought

Finally, choosing the suitable bolts and machining options is critical for boosting and optimizing procedures productivity. The combination of these components can significantly affect the performance and high quality of procedures. By thoroughly taking into consideration the compatibility and precision of bolts and equipment, seamless operations can be attained, resulting in boosted overall performance and success in numerous markets.

In the intricate landscape of industrial procedures, the function of bolts and machining solutions commonly goes unnoticed, yet their importance in making sure effective and smooth procedures can not be overstated.One essential factor to consider when picking fasteners is to match the material of the fastener with the products being signed up with. Furthermore, utilizing advanced machining techniques and modern technologies can better boost the assimilation procedure by making certain precise fitting and alignment of fasteners within the machinery parts.

By very carefully choosing the best fasteners and machining solutions, makers can enhance their manufacturing procedures, leading to boosted efficiency and output. Precision machining makes certain that elements are properly refined, fitting together flawlessly with bolts for a trusted and specific end item.